-

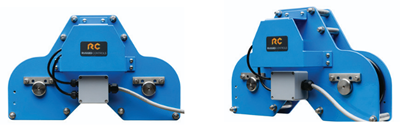

Heavy-duty and highly accurate for all types of line monitoring systems.

-

Running Line Tensiometers (RLTs) are an essential component for both new and existing winch or hoist systems that enable monitoring of line tension, speed, and payout.

-

All models feature a durable, compact design and install quickly and easily.

FEATURES AND BENEFITS:

![]() Compatible with many types of cable/rope, including wire rope, EM, fiber optic, synthetic cable, and fiber rope. One product, multiple uses.

Compatible with many types of cable/rope, including wire rope, EM, fiber optic, synthetic cable, and fiber rope. One product, multiple uses.

![]() All electronics safely located in center sensing head to prevent accidental damage or contamination.

All electronics safely located in center sensing head to prevent accidental damage or contamination.

![]() Sold separately, or paired with Rugged Controls RPC Displays. When paired with an RPC-90x or RPC-80x display, the system provides winch operators with real-time line parameter monitoring.

Sold separately, or paired with Rugged Controls RPC Displays. When paired with an RPC-90x or RPC-80x display, the system provides winch operators with real-time line parameter monitoring.

![]() Sealed roller bearings rated for high static and dynamic tension loads. High line speed rating under full load allows for reduced maintenance requirements and the ability to measure tension at high line velocities.

Sealed roller bearings rated for high static and dynamic tension loads. High line speed rating under full load allows for reduced maintenance requirements and the ability to measure tension at high line velocities.

![]() Constructed from thermoplastic coated tool steel with 316 stainless steel fasteners and 4340 hardened steel sheaves. Ideal for withstanding exposure to harsh or hazardous conditions.

Constructed from thermoplastic coated tool steel with 316 stainless steel fasteners and 4340 hardened steel sheaves. Ideal for withstanding exposure to harsh or hazardous conditions.

![]() Design validated by both finite element analysis (FEA) and in-field testing for the highest degree of confidence in product performance and integrity. Industry leading factor of safety of minimum 2.5x full scale rating.

Design validated by both finite element analysis (FEA) and in-field testing for the highest degree of confidence in product performance and integrity. Industry leading factor of safety of minimum 2.5x full scale rating.

![]() Custom designs available to accommodate nonstandard cable/rope diameters. Contact Rugged Controls if needed.

Custom designs available to accommodate nonstandard cable/rope diameters. Contact Rugged Controls if needed.

![]() Ideal for new and retrofit applications. Fast and accurate data collection when you need it, where you need it.

Ideal for new and retrofit applications. Fast and accurate data collection when you need it, where you need it.

![]() Hazardous rated sensors are optionally available. Contact Rugged Controls if needed.

Hazardous rated sensors are optionally available. Contact Rugged Controls if needed.

![]() Complete line monitoring systems available for rent. Contact Rugged Controls for more information.

Complete line monitoring systems available for rent. Contact Rugged Controls for more information.

![]() Custom solutions available. Contact Rugged Controls for more information.

Custom solutions available. Contact Rugged Controls for more information.