Measurement Technology NW (MTNW) implemented its running line tensiometer (RLT) technology with a Samson synthetic rope in an offshore mooring monitoring project engineered by Delmar Systems.

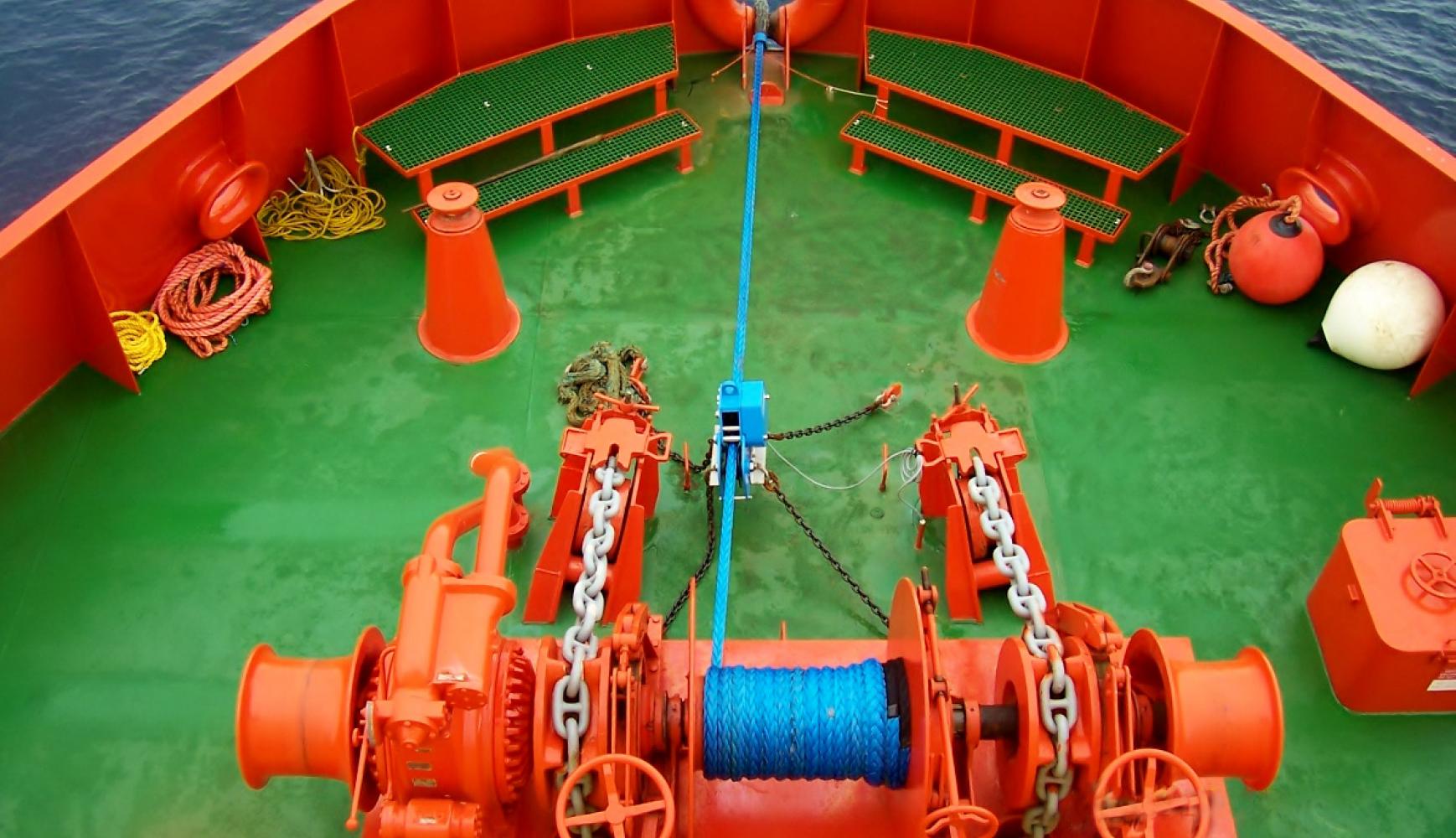

This implementation is MTNW’s first use of tension measurement technology with 2”+ synthetic ropes. Recently, Delmar Systems was contracted to moor an offshore supply vessel (OSV) to a major offshore platform in the Gulf of Mexico. The OSV is being used as a support vessel while dive operations are conducted. The OSV is using a three-point mooring system consisting of two stern hawser lines attached to the platform and a bow mooring line attached to a preset suction pile foundation in 2,900 feet of water. The mooring system had to be as robust as possible while still maintaining ease of handling and rigging by the vessel crew.

To achieve a higher Maximum Breaking Load on the OSV bow mooring line while maintaining deck maneuverability, Delmar chose Samson’s AmSteel-Blue HMPE rope made of high modulus polypropylene (HMPE) as the bow winch line. An MTNW RL-20175K running line tensiometer provided tension measurement for the bow line. During the design phase of the project, MTNW thoroughly tested and calibrated the RLT using the specified 2¼" AmSteel-Blue rope.

“This is MTNWs first use of an RLT to measure tension in a major synthetic mooring line of this large diameter,” said Tom Rezanka, SVP of MTNW. “Our RLTs are more commonly used to measure the tension of wire rope, but synthetic lines have different mechanical characteristics under load. We were able to collaborate closely with the R&D engineers at Samson. The monitoring system was fully tested, calibrated and witnessed on an ABS-certified test bed with the resulting accuracy identical to wire rope applications. The trend in mooring is lighter and stronger, which will require increased use of synthetic ropes and new, modern technologies to monitor them. Our sensors and systems are proven to work with any lines.”

“Both the AmSteel-Blue winch line and MTNW’s RLT have been working flawlessly together and have played a vital role in the success of the project,” said Dillon Shuler, engineer at Delmar Systems. Rezanka explains, “MTNW RLTs are being used more frequently for mooring monitoring because our modern design provides a rapidly deployable solution for retrofitting existing winches. We can deploy on virtually any winch, with an installation time measured in hours, not weeks or months.”

“Since the Macondo oil spill, we have seen a significant increase in interest from risk managers and lifting/rigging engineers for determining line and cable tensions in all environments,” said Rezanka. “If it can be monitored, alerted on, and data-logged to a computer it needs to be. Our solutions support the increasing safety requirements for offshore operations and allow project managers to sleep better at night.” Original article can be found at: http://www.marinelink.com/news/approaches-offshore340216.aspx