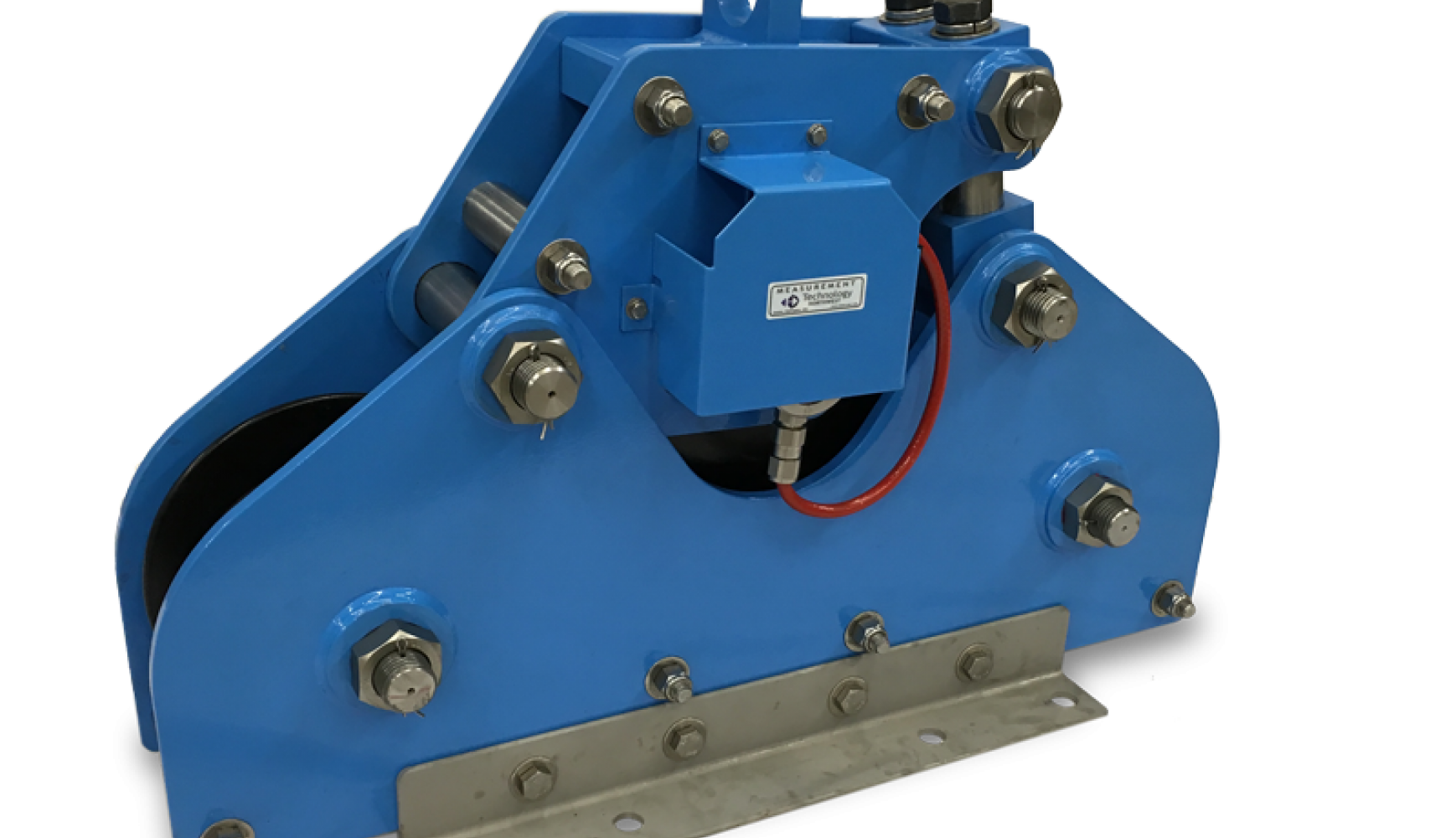

We have recently released an addition to our Variable Wire Diameter (VWD) line of Running Line Tensiometers, the RL-30-VWD.

Our VWD models provide a versatile solution for customers looking to monitor line tension, speed, and payout on multiple wire rope sizes without purchasing multiple tensiometers or sheave assemblies.

Our VWDs are suitable for the most aggressive offshore marine applications with anti-corrosive thermoplastic coated Alloy Steel frames. Fully hardened 4340 Alloy Steel sheaves with spherical roller bearings offer high line speed ratings, increased wear resistance and service life. Validated by FEA analysis, our VWD tensiometers offer a 2.5 to 1 ultimate safety factor with +/- 1%FS tension accuracy.

The new VWD version of our running line tensiometers provides operators with more flexibility and versatility when choosing the equipment that will support their requirements.

Typical Applications:

- Spooling

- Offshore Mooring

- Barge Mooring

- Oceanographic Payload Monitoring

- Cable Pulling / Pipeline inspection

- Offshore Construction

- Rentals

RL-30-VWD Features:

- Provides line tension, speed, and payout measurement

- Accommodates 1.5" to 3" wire rope, synthetic rope and cable without swapping sheaves

- Precision tension accuracy - greater than +/- 1% FS

- Perfect for spooling projects and temporary mooring projects

- 200 Ton Max Tension Capacity

- Available for short or long term rentals from our Seattle, WA or Houma, LA rental inventory

Tensiometer Construction |

|

|---|---|

| Frame | Alloy Steel with Marine Grade Coating |

| Fasteners | 316 Stainless Steel |

| Pins & Shafts | 17-4PH Stainless Steel |

| Sheaves | 4340 Alloy Steel with Marine Coating |

| Bearings | Sealed Regreasable Roller Bearings |

| Enclosure | Nema 4X Stainless Steel |

| Tension Accuracy | +/- 1% of Rated Capacity |

| Payout Accuracy | 6-8 targets per sheave revolution - 1.0" Resolution typical |

| Ultimate Safety Factor | 250% of Rated Capacity without mechanical failure |