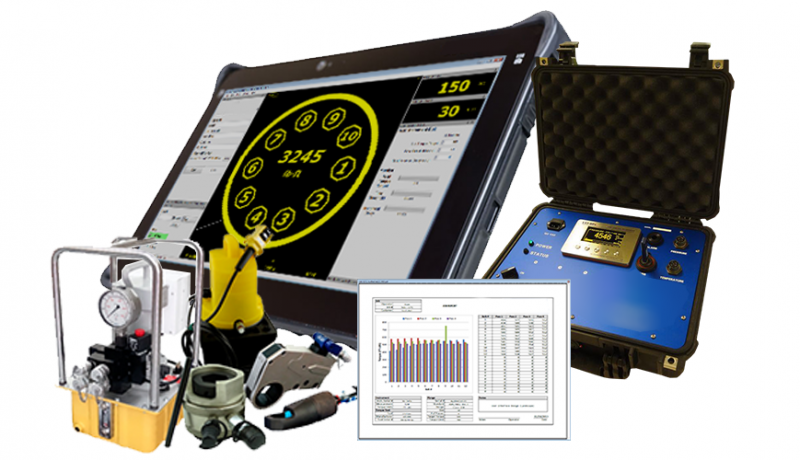

TorqueDAC saves time and labor while ensuring greater torqueing accuracy. This single tool allows you to easily and accurately torque using all manufacturers hydraulic bolting equipment.

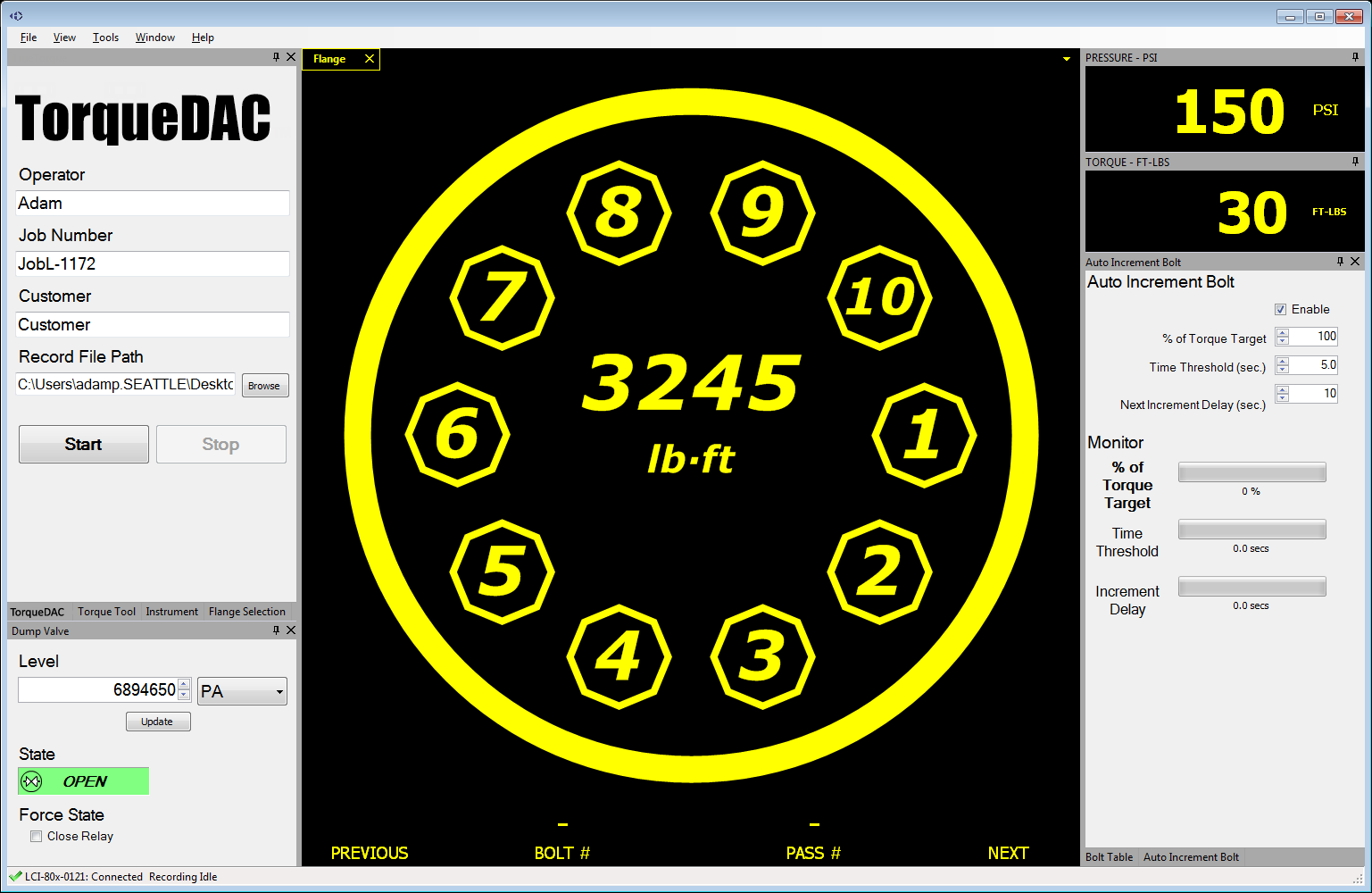

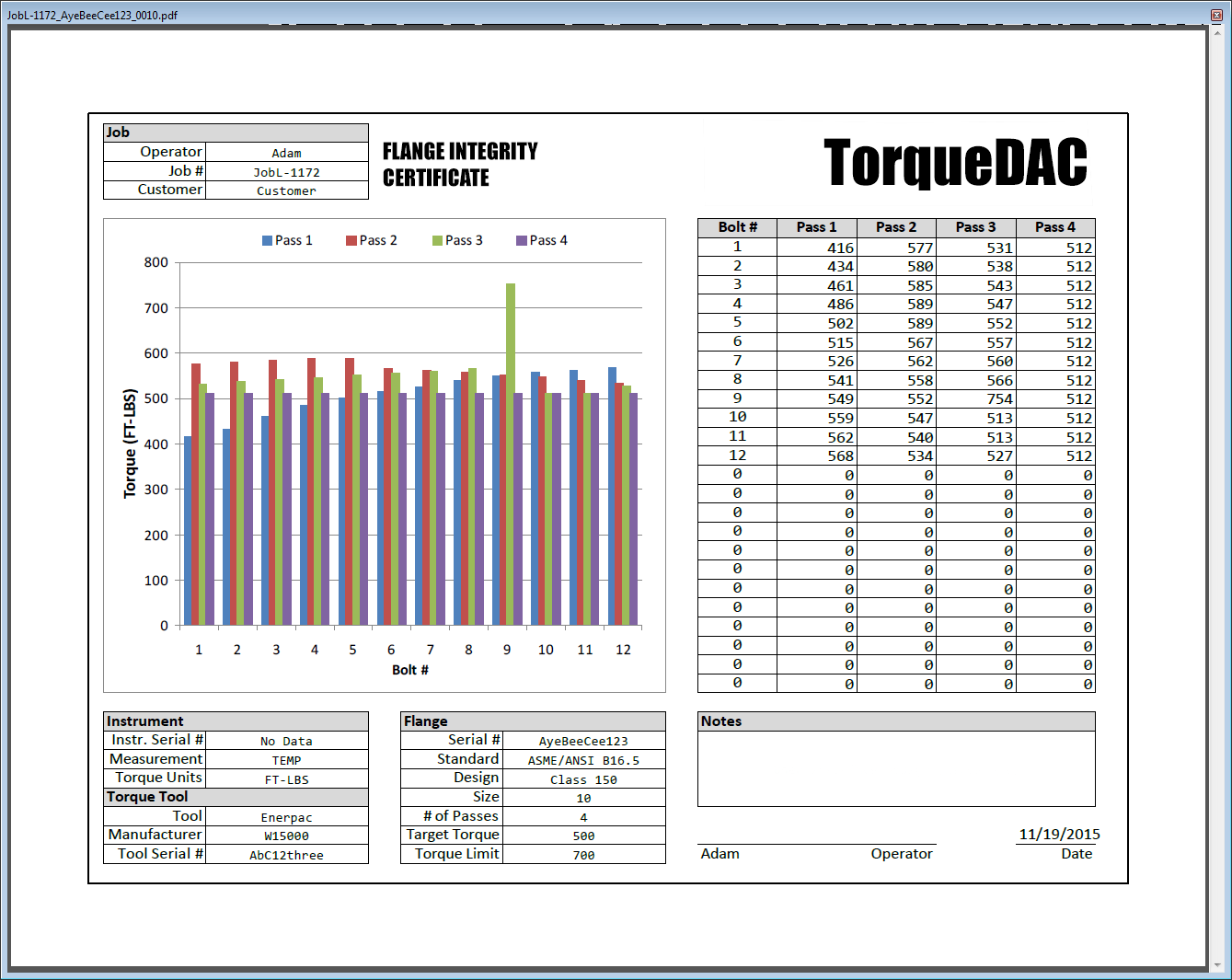

The flange indicator provides a step by step process guide, showing selected bolt, peak torque, flange design, bolting sequence, number of passes and status. Reports are easily created for each flange or job for process traceability, liability and integrity.

Faster, More Accurate and Easier to Use

- .25% Sensor Accuracy

- Compatible with all manufacturer's hydraulic bolting equipment

- Easily generated comprehensive reports

- Step-by-step guide

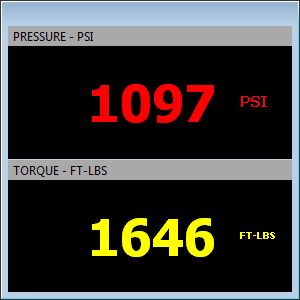

- Accurately converts bolting HPU PSI to torque measurement

- Visual and audible indicators

- Controller interface provides numeric, bar graph, and easy to follow indicators

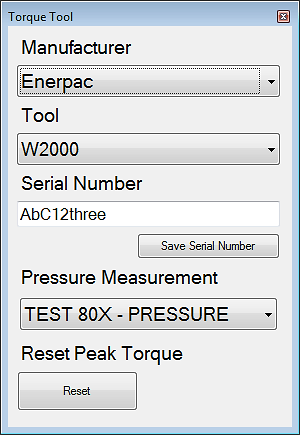

- Easily swap bolting tool heads via software menus

- Visual and audible set points indicate under/optimal/and over torque status

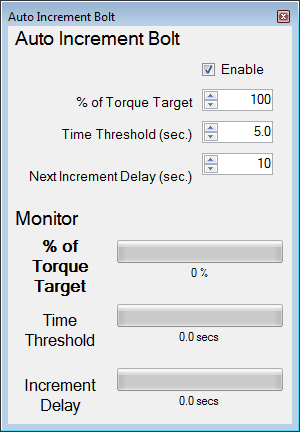

- Auto Bolter feature will automatically realease tool pressure when optimal torque is achieved

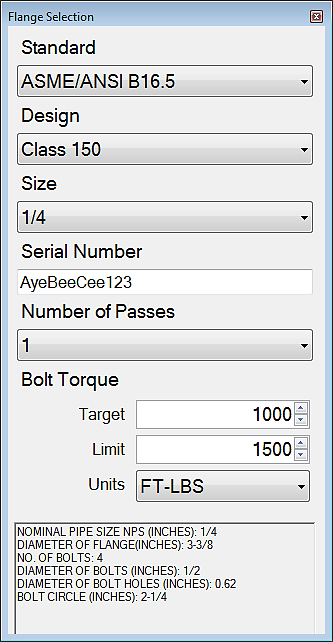

- Set point alarms are configurable for bolt torque, or automatic per ASME/API specification

- Optional wireless interface, and angle/turns measurement

- Software/Hardware works with 3rd party sensors

| Hardware | |

|---|---|

|

Wireless Tablet with TorqueDAC software |

LCI-80x Automation Pack |

| Software | |

|

Standard TorqueDAC Interface |

Numeric Indicator |

|

Torque Tool Configuration |

Flange Configuration |

|

Auto-Bolter Configuration |

|

| Report | |

|

Brandable PDF Reports can be saved locally, pushed to the web, or emailed directly to the customer |

|