Rugged Controls has worked with Foss tugs to provide winch monitoring solutions for their tugboats involved in ship assist and tanker escort services. Interfacing LCI local displays to existing load pins installed on both ends of each brakeband and rotational sensors on the drum, Rugged Controls provided tugboat operators an accurate and reliable display of tension, speed and scope. Layer compensation algorithms were required to compensate for changing circumference as the line spools on or off the drum.

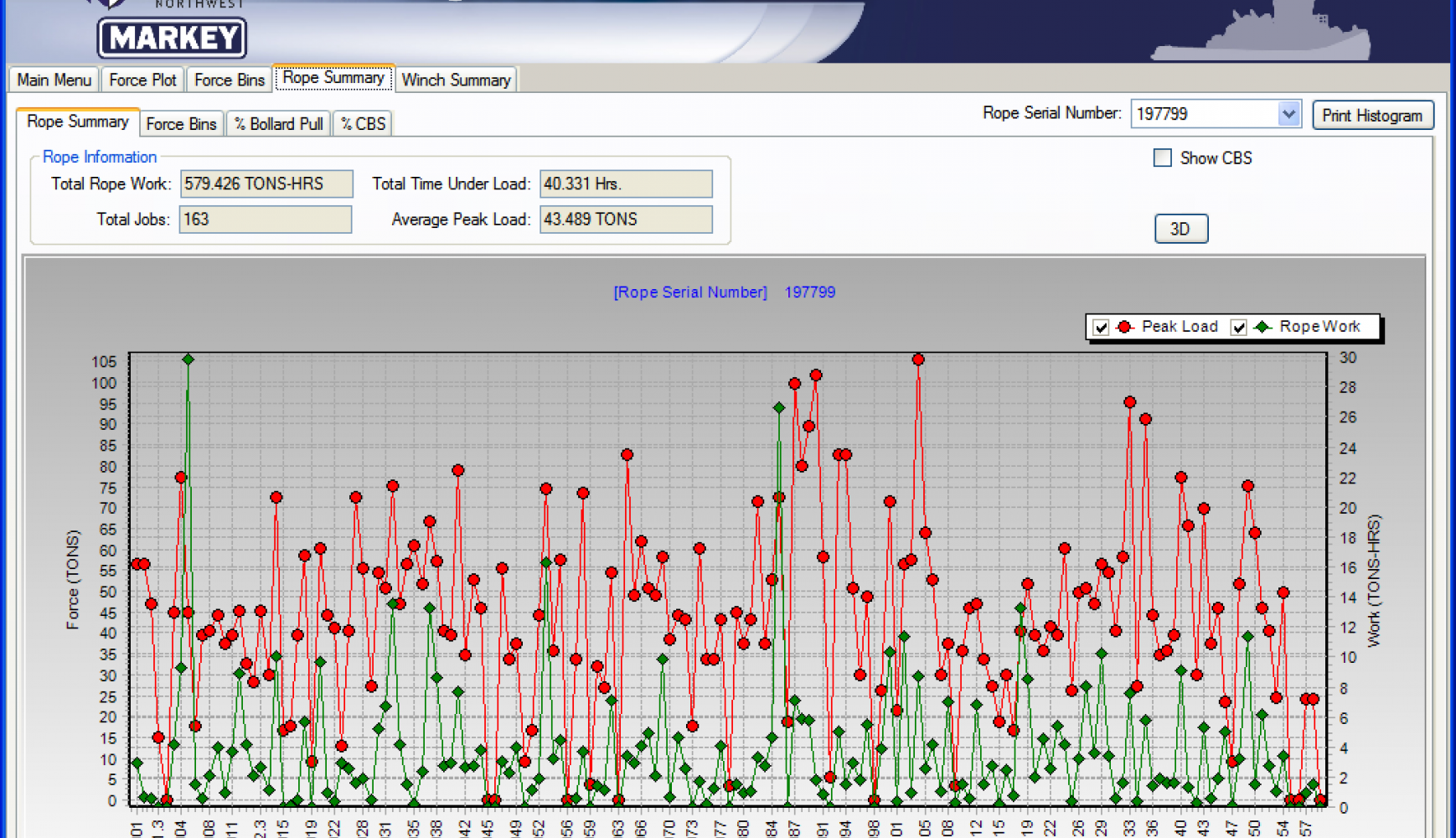

Additionally Rugged Controls teamed with the tugboat operators, winch manufacturers, and the synthetic line manufacturers to design a software monitoring solution aimed at tracking long term tension data on the hawser line to aid in determining retire criteria for this very expensive capital investment. The software can be installed with or without our LCI local displays, it can operate in a stand alone mode or connected to existing PLC monitoring systems. Hawser line tension data was logged for each job (defined as a specific escort for a specific vessel) and analysized for peak tension and rope work. A data set was held for the entire life or usage of the hawser line or pendant. Also having the time series of the hawser line tension helped in identifying dynamic tension events that could damage the synthetic line.

"The issue of line integrity is absolutely paramount," said Joel Altus, supervisor of vessel rigging at Foss Maritime. "The towline is the singular connection between the tug and the vessel. There isn’t anyone who isn’t vitally concerned about it."