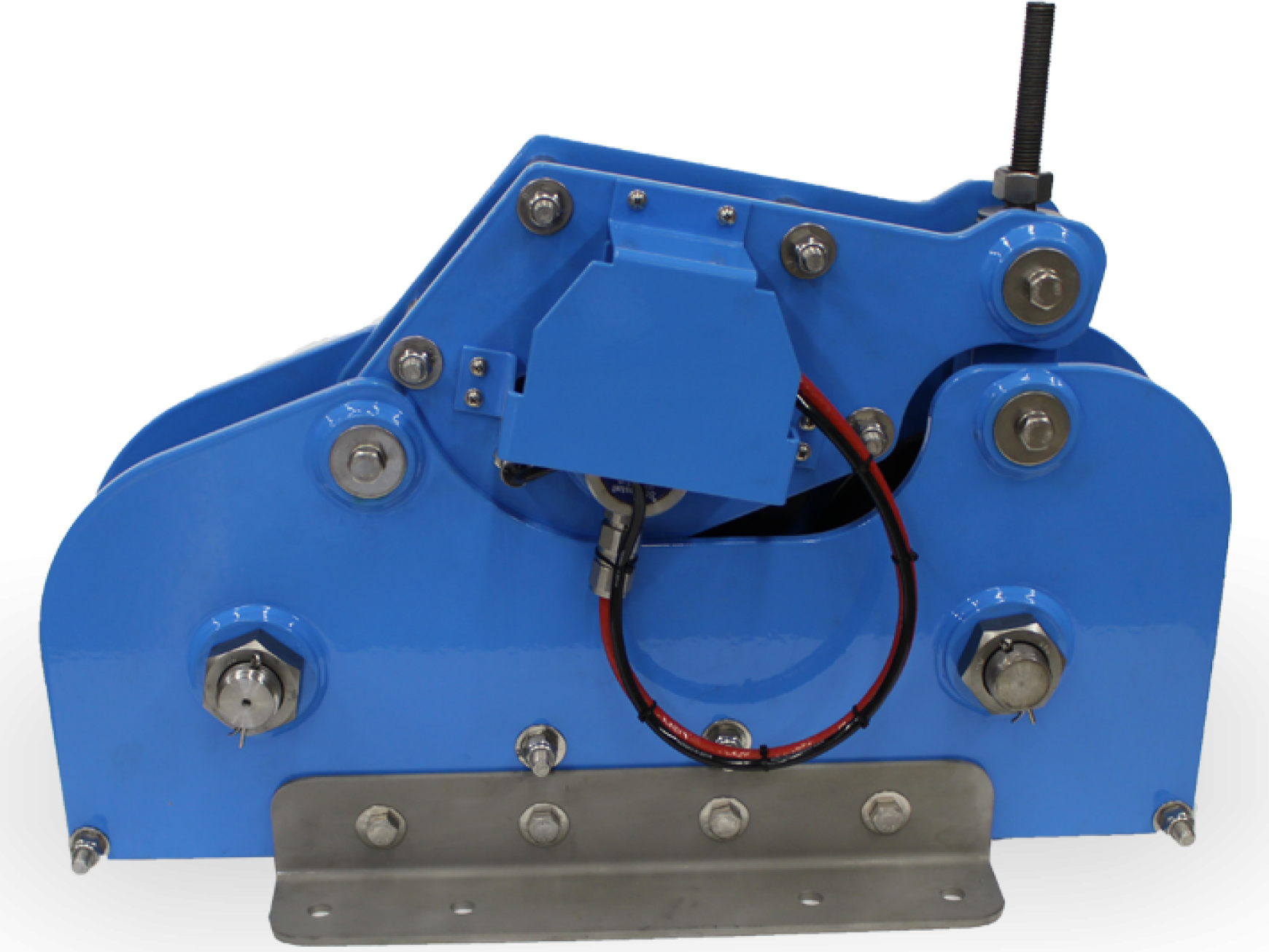

We have recently developed and started selling the Variable Wire Diameter (VWD) versions of our RL10, RL20 & RL30 tensiometers.

These models provide a versatile solution for customers looking to monitor line tension speed and payout on multiple wire rope sizes without purchasing multiple tensiometers or sheave assemblies.

The VWD is easily swapped from one wire rope to the next by a single operator by utilizing our Removable Center Sheave feature and Jacking Screws. The RL10 VWD is suitable for wire... + continue reading

Our Blog

Thursday, March 27, 2014 - 10:00

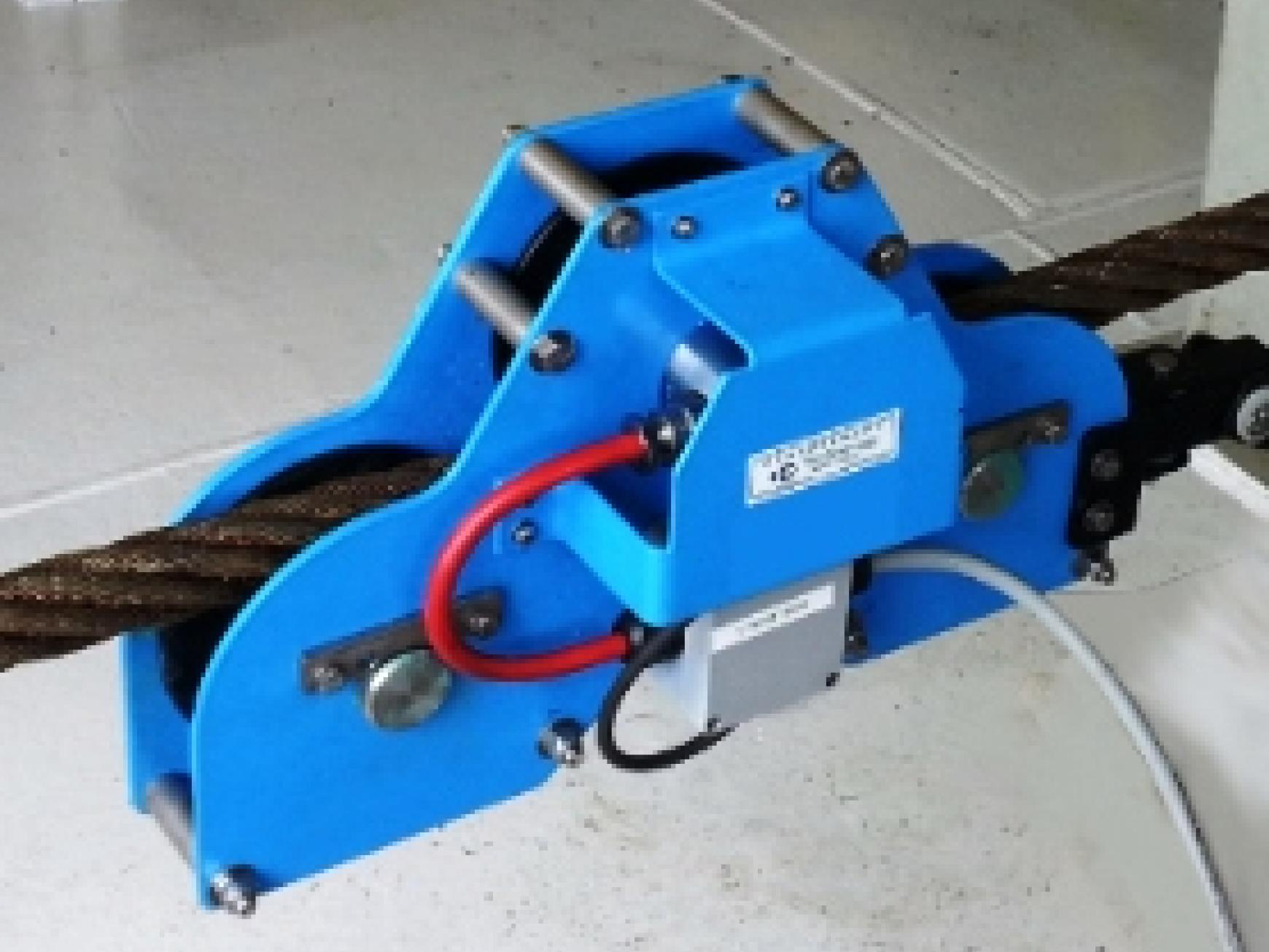

Just released our new How To Video - How to Install MTNW Running Line Tensiometers on Wire Rope - featuring our RL-30 Running Line Tensiometer (RLT) for up to 375 Tons max tension and up to 3" wire rope diameter. Typical applications for the RL-30 include monitoring anchor winch tension, speed, and payout on Drillships, Semisubs, and other Offshore Rigs. This video gives step by step instruction on how to install our Running Line Tensiometers with the "... + continue reading

Wednesday, March 5, 2014 - 14:49

MTNW provided two instrumented Skookum VLS-30 Vertical Lead Sheave assemblies for 1.5” wire rope, one LCI-90i Display, and a laptop running WinchDAC software.Instrumented for Tension, Speed, and Payout, these 30” Sheaves are rated to 50 Tons max tension. They will remain in MTNW’s fleet for weekly or monthly rental.The Lucious Truss Spar is located in approximately 7,100 feet of water depth in the US Gulf of Mexico and will have a capacity of 80,000 barrels of oil per day and 450 million cubic feet of natural gas per day. ... + continue reading

Monday, November 4, 2013 - 09:22

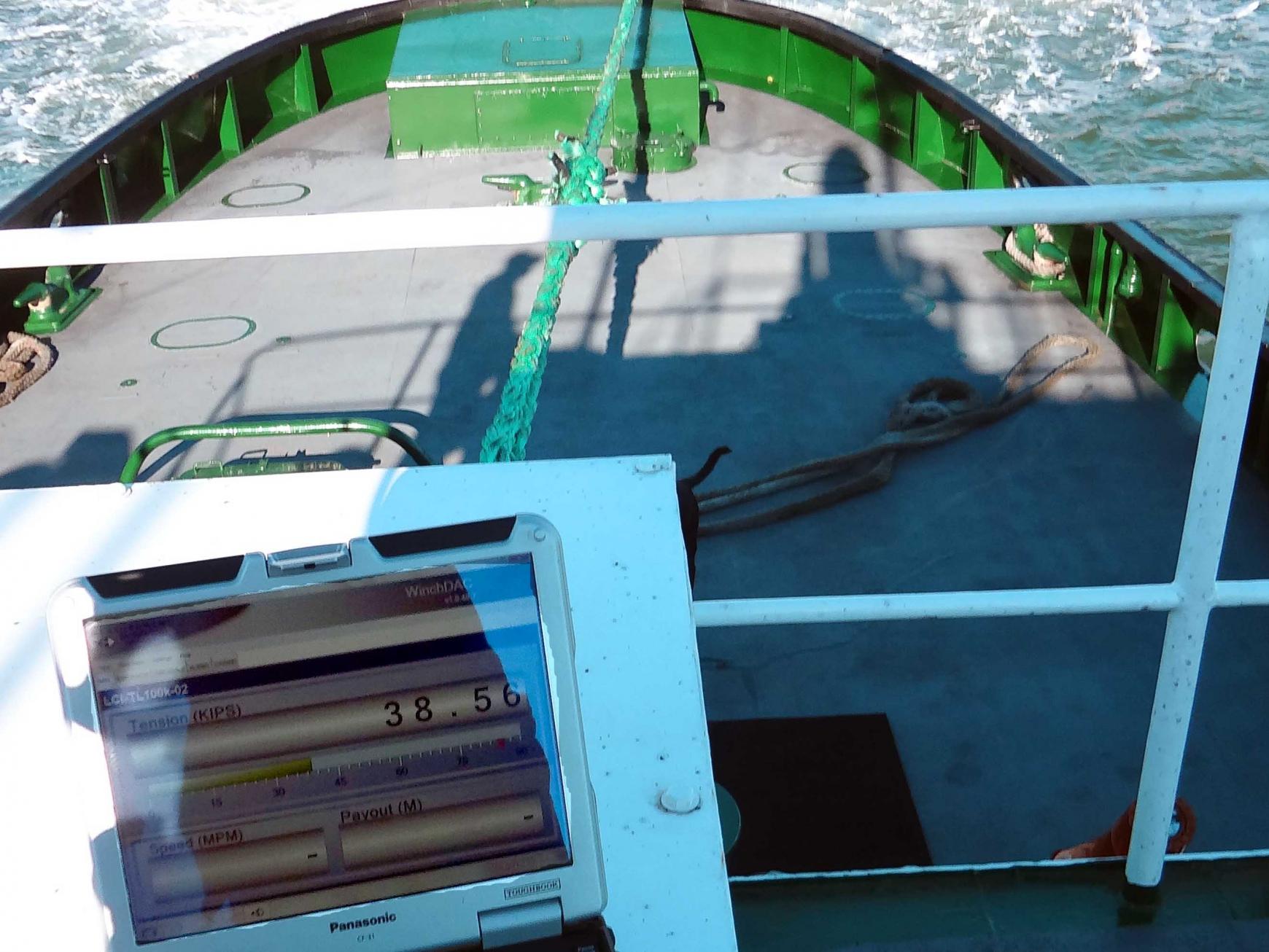

Many arguments about the capabilities of a tug can be quickly settled when you can conduct a full-ahead power, bollard pull test.“Many captains will argue about horsepower, hull design, rudder angles, and other variables, but the only thing that really matters is bollard pull and a test provides empirical data of pure power,” says Mark Babcock, VP of Machinery for Sause Brothers’ 200 tugs, barges and OSVs. “A well maintained vessel shouldn’t lose bollard pull over time, but with every propulsion related change, engine overhaul, shaft or... + continue reading

Thursday, August 29, 2013 - 15:28

***FOR IMMEDIATE RELEASE***

MTNW’s next-generation Rugged Programmable Controller approved for use in Class I, Division 2, T5, Group A, B, C, and D hazardous locations

August 29, 2013. Seattle, WA. Measurement Technology NW (MTNW) announces its LCI-90i-IS Rugged Programmable Controller (RPC) has been awarded the globally recognized Underwriters Laboratories (UL) certification. UL quality approval allows customers to use the industry leading RPC in hazardous applications without additional testing or... + continue reading

Thursday, March 28, 2013 - 17:18

Measurement Technology NW (MTNW) announces 3 new jack-up mooring winch monitoring projects with Transocean Magellan & Constellation I and the Rowan California.“In many parts of the world, the tidal forces, lack of access to qualified tugboats, and close proximity to subsea pipelines require rig owners to install mooring winches on jack-ups,” said Tom Rezanka, Vice President, MTNW. “A mooring winch monitoring system can provide jack-up managers with decimal point accuracy and therefore lower risk when they are ready to drop their... + continue reading

Thursday, March 21, 2013 - 16:43

We were excited to see an article on advances in bollard pull testing by Joseph Keefe on MarineLink.com that references some of our recent work in the field. Read more about bollard pull testing techniques and challenges as well as some great info on our portable plug-and-play data logging solutions by clicking here.

Monday, March 4, 2013 - 12:15

We have recently developed and started selling the Single Side Plate (SSP) versions of our RL-10 & RL-20 tensiometers. These are a lower cost option in our fleet of running line tensiometers (RLTs or cable line riders).The SSP reduces the manufacturing complexity and weight (and therefore cost) of the tensiometer while maintaining the same tension and wire diameter capacities.The original Removable Center Sheave RLT design allowed operators to quickly install and remove a tensiometer from a fixed line. For RLTs which will stay... + continue reading

Tuesday, January 15, 2013 - 09:05

January 15, 2013. Seattle, WA. Measurement Technology NW (MTNW) has recently developed a new rental fleet of tension measuring links, shackles, running line tensiometers, and data-logging equipment. This fleet of devices will measure line tension up to 1,000,000lbs. “Over the years, we have offered equipment for bollard pull testing and certification for tugboats and now we have invested in and made available a fleet of rental devices so that more naval architects, tugboat operations managers, and engineers can perform... + continue reading

Tuesday, November 27, 2012 - 15:48

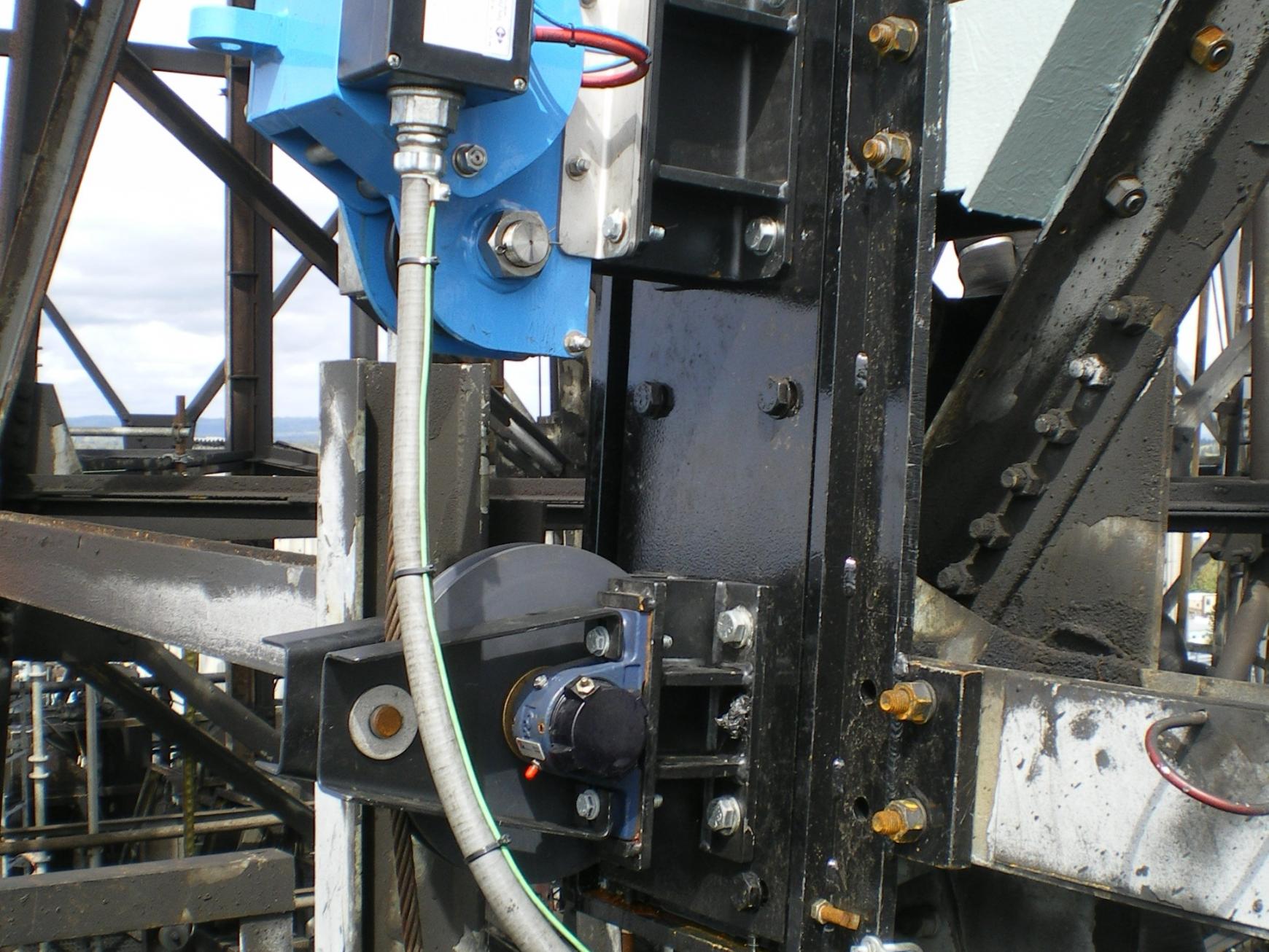

The decoking operations team at BP Cherry Point (Washington State) worked with Bayside Engineering of Lynden, WA to retrofit an existing decoking cutting-head and winch system.Based on several retrofits that MTNW had completed with Flowserve, Bayside chose to work with our RL-1013KR-IS instrinsically safe running line tensiometers.These tensiometers contain both force and rotational sensors and can be rapidly deployed onto existing cables.The operations team decided to fix mount these RLTs between the turning sheave at the bottom and the crown... + continue reading