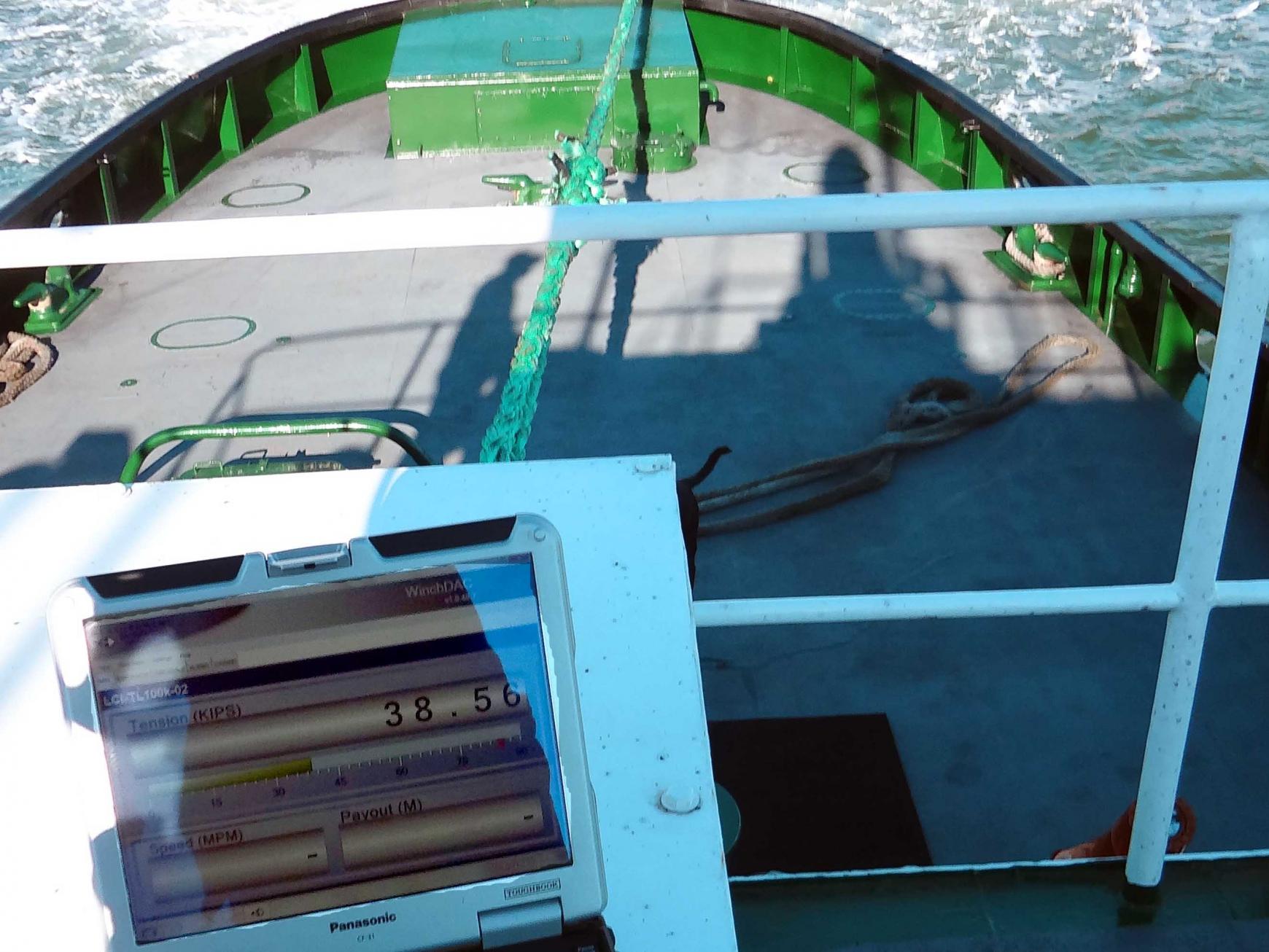

Many arguments about the capabilities of a tug can be quickly settled when you can conduct a full-ahead power, bollard pull test.“Many captains will argue about horsepower, hull design, rudder angles, and other variables, but the only thing that really matters is bollard pull and a test provides empirical data of pure power,” says Mark Babcock, VP of Machinery for Sause Brothers’ 200 tugs, barges and OSVs. “A well maintained vessel shouldn’t lose bollard pull over time, but with every propulsion related change, engine overhaul, shaft or... + continue reading

Our Blog

Thursday, August 29, 2013 - 15:28

***FOR IMMEDIATE RELEASE***

MTNW’s next-generation Rugged Programmable Controller approved for use in Class I, Division 2, T5, Group A, B, C, and D hazardous locations

August 29, 2013. Seattle, WA. Measurement Technology NW (MTNW) announces its LCI-90i-IS Rugged Programmable Controller (RPC) has been awarded the globally recognized Underwriters Laboratories (UL) certification. UL quality approval allows customers to use the industry leading RPC in hazardous applications without additional testing or... + continue reading

Thursday, March 28, 2013 - 17:18

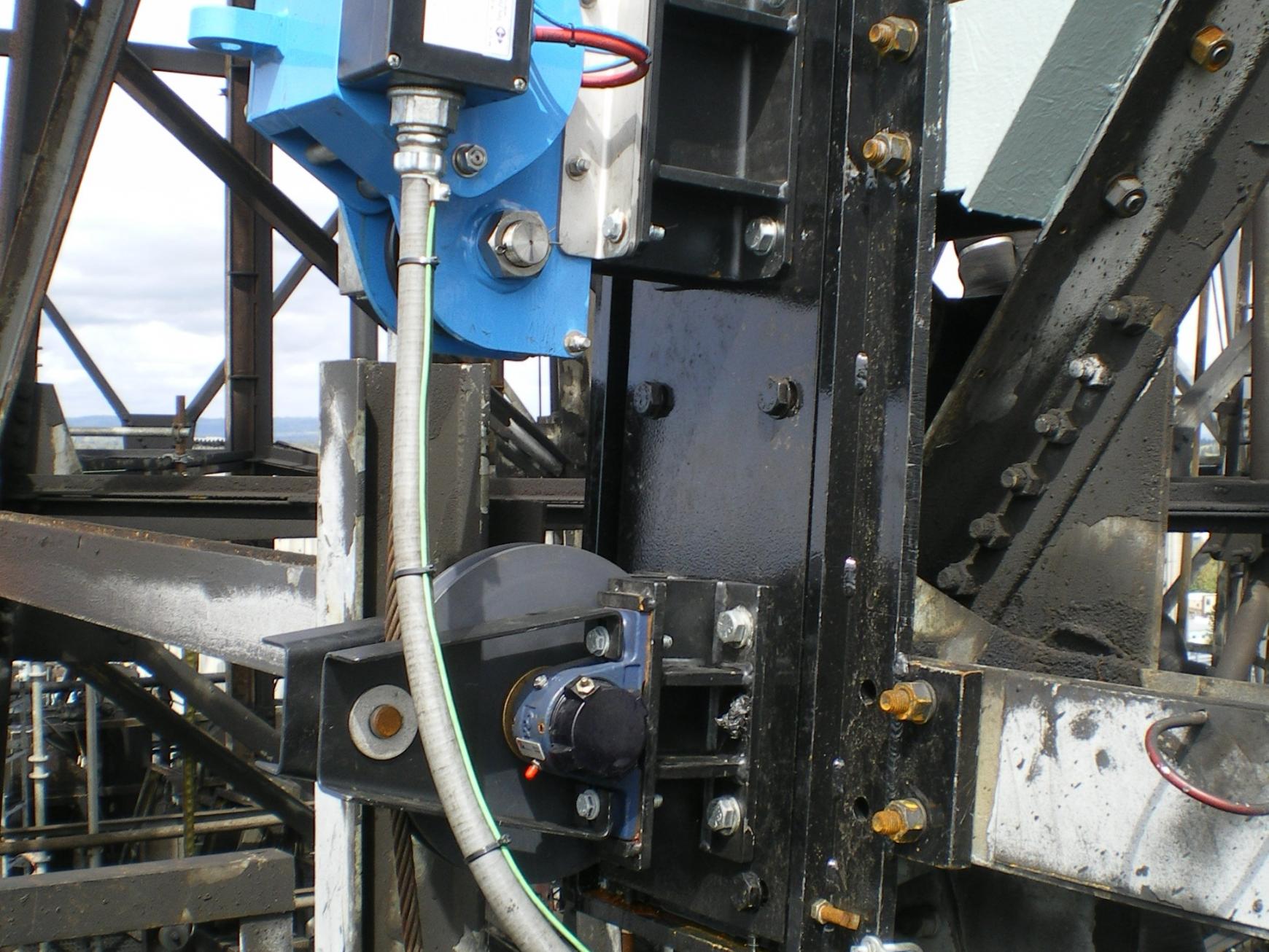

Measurement Technology NW (MTNW) announces 3 new jack-up mooring winch monitoring projects with Transocean Magellan & Constellation I and the Rowan California.“In many parts of the world, the tidal forces, lack of access to qualified tugboats, and close proximity to subsea pipelines require rig owners to install mooring winches on jack-ups,” said Tom Rezanka, Vice President, MTNW. “A mooring winch monitoring system can provide jack-up managers with decimal point accuracy and therefore lower risk when they are ready to drop their... + continue reading

Thursday, March 21, 2013 - 16:43

We were excited to see an article on advances in bollard pull testing by Joseph Keefe on MarineLink.com that references some of our recent work in the field. Read more about bollard pull testing techniques and challenges as well as some great info on our portable plug-and-play data logging solutions by clicking here.

Monday, March 4, 2013 - 12:15

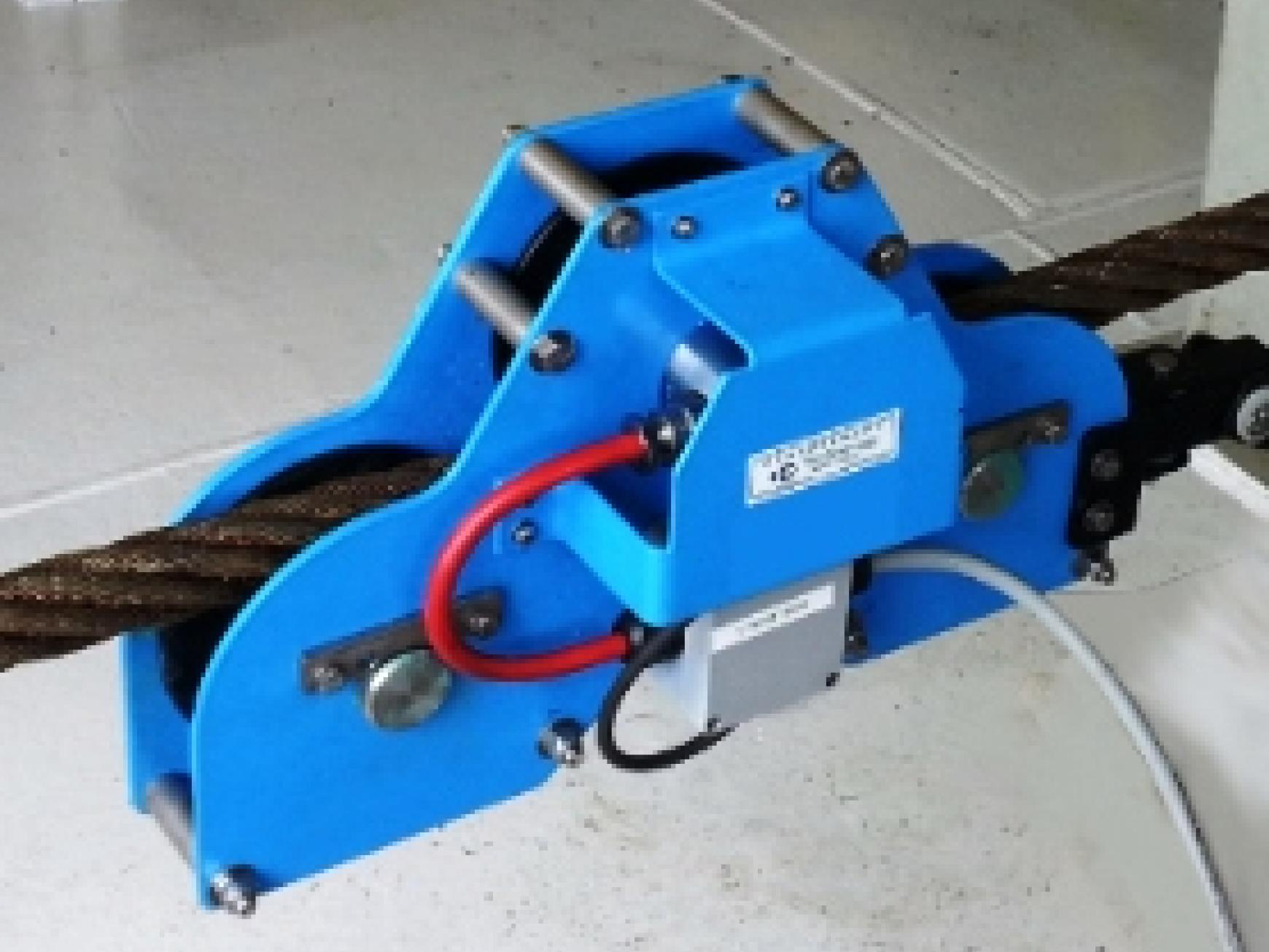

We have recently developed and started selling the Single Side Plate (SSP) versions of our RL-10 & RL-20 tensiometers. These are a lower cost option in our fleet of running line tensiometers (RLTs or cable line riders).The SSP reduces the manufacturing complexity and weight (and therefore cost) of the tensiometer while maintaining the same tension and wire diameter capacities.The original Removable Center Sheave RLT design allowed operators to quickly install and remove a tensiometer from a fixed line. For RLTs which will stay... + continue reading

Tuesday, January 15, 2013 - 09:05

January 15, 2013. Seattle, WA. Measurement Technology NW (MTNW) has recently developed a new rental fleet of tension measuring links, shackles, running line tensiometers, and data-logging equipment. This fleet of devices will measure line tension up to 1,000,000lbs. “Over the years, we have offered equipment for bollard pull testing and certification for tugboats and now we have invested in and made available a fleet of rental devices so that more naval architects, tugboat operations managers, and engineers can perform... + continue reading

Tuesday, November 27, 2012 - 15:48

The decoking operations team at BP Cherry Point (Washington State) worked with Bayside Engineering of Lynden, WA to retrofit an existing decoking cutting-head and winch system.Based on several retrofits that MTNW had completed with Flowserve, Bayside chose to work with our RL-1013KR-IS instrinsically safe running line tensiometers.These tensiometers contain both force and rotational sensors and can be rapidly deployed onto existing cables.The operations team decided to fix mount these RLTs between the turning sheave at the bottom and the crown... + continue reading

Tuesday, November 27, 2012 - 13:45

In conjunction with Thern, Liquid Waste Technology, CH2M Hill & the US Army Corp, MTNW installed 15 RL-05 running line tensiometers (RLTs) to monitor line tension on the winches supporting the Washington Aqueduct Settling Ponds.A primary challenge facing complex winch installations with multiple turning sheaves, large cable runs, and remote operations is understanding line tension while the winches are in operation. Going from theoretical loads to the real world line tension can often provide surprising results. In support of operator... + continue reading

Monday, March 26, 2012 - 14:47

We’ve recently completed the instrumentation of the largest sheave assembly we have had come through our shop. Last year, we were approached by Tidewater to build a hanging sheave assembly for a workboat A-frame that would accommodate the bending radius of 1.5” Amsteel Blue rope and 60,000lbs, the peak expected tension of the application.We worked with Supreme Integrated Technologies (of Harahan, LA) and Skookum, an Ulven Forging company (or Hubbard, OR), to build a 6 foot tall and 3.5 foot wide sheave. To provide payout and speed monitoring,... + continue reading

Friday, February 3, 2012 - 19:13

The Offshore Oil & Gas industry takes us to remote parts of the world that provides unique challenges and dangers. Our offshore customers, Noble, Rowan, and others require our engineers to go through BOSIET training. The BOSIET (Basic Offshore Safety Induction and Emergency Training) program at the Marine Survival Training Center in Lafayette, LA is a three day course that introduces marine offshore hazards, safety techniques and equipment, and basic sea survival. Recently, one of our engineers, Adam Przybilla, went through this... + continue reading